Advanced Biodegradable Resin Compounding with CTE’s HTM Twin-Screw Extruder

CTE’s HTM Twin-Screw Extruder minimizes resin degradation with advanced heat suppression and dispersion, enabling high-quality biodegradable resin compounding.

CTE’s HTM Twin-Screw Extruder minimizes resin degradation with advanced heat suppression and dispersion, enabling high-quality biodegradable resin compounding.

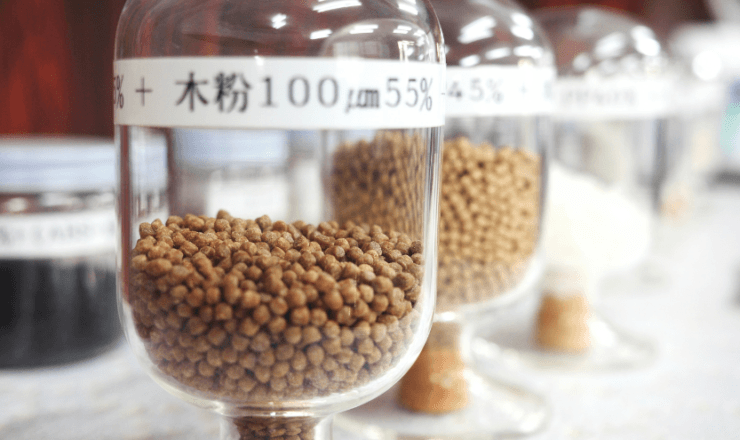

CTE’s HTM Twin-Screw Extruder transforms biomass compounding by tackling low density, moisture, and heat sensitivity, ensuring high-quality, sustainable materials for various industries.

Explore CTE’s advanced extrusion for low-bulk-density materials. The HTM Twin-Screw Extruder ensures optimized feeding, superior degassing, and efficient processing of biomass, fillers, and recycled plastics.

Plastic extruders are essential for producing various plastic products. This article breaks down the key mechanisms of plastic extruders, offering a simplified understanding of their role in manufacturing.