Hot Cut System

- #Peripheral

CTE Hot-Cut System: Usability and Customizability in One

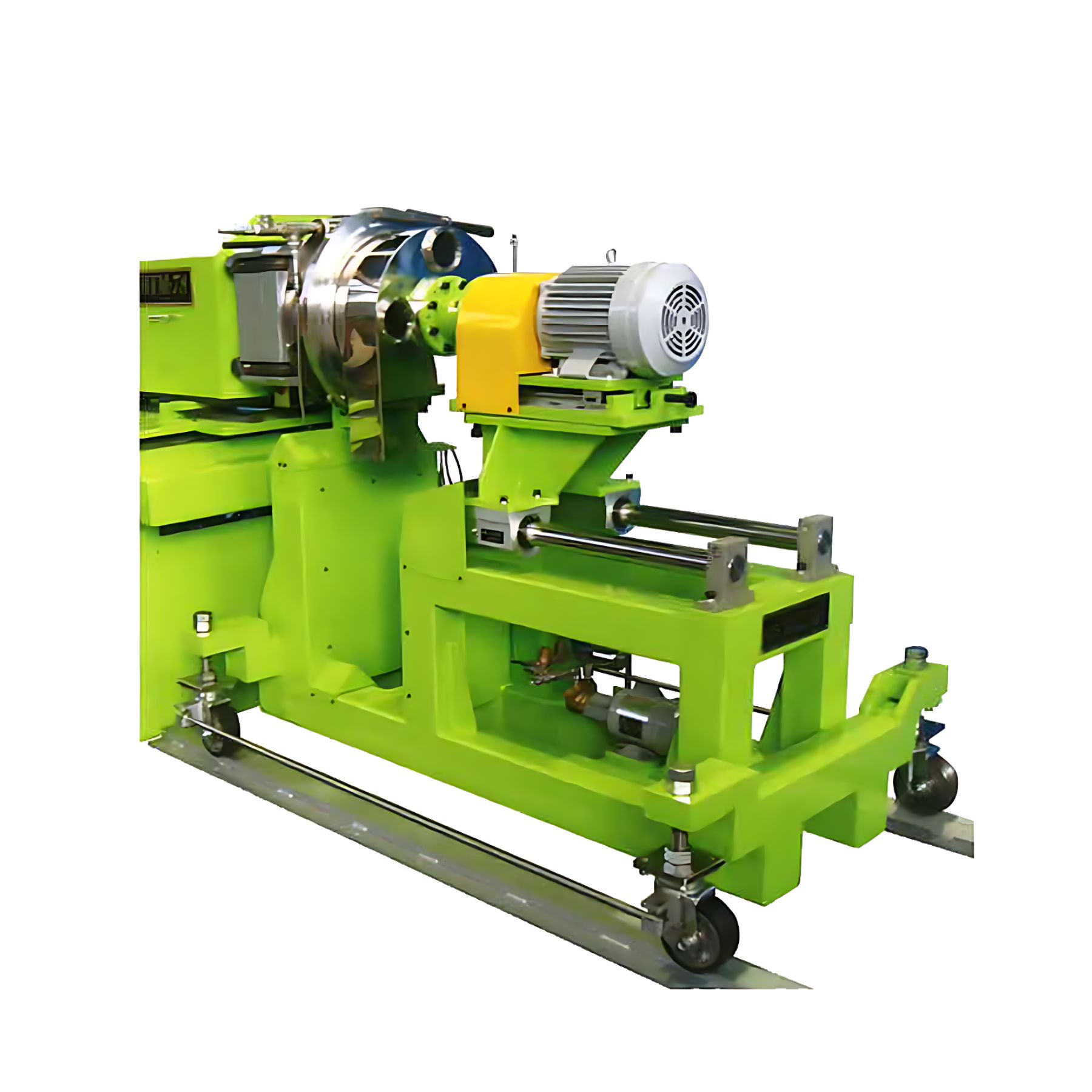

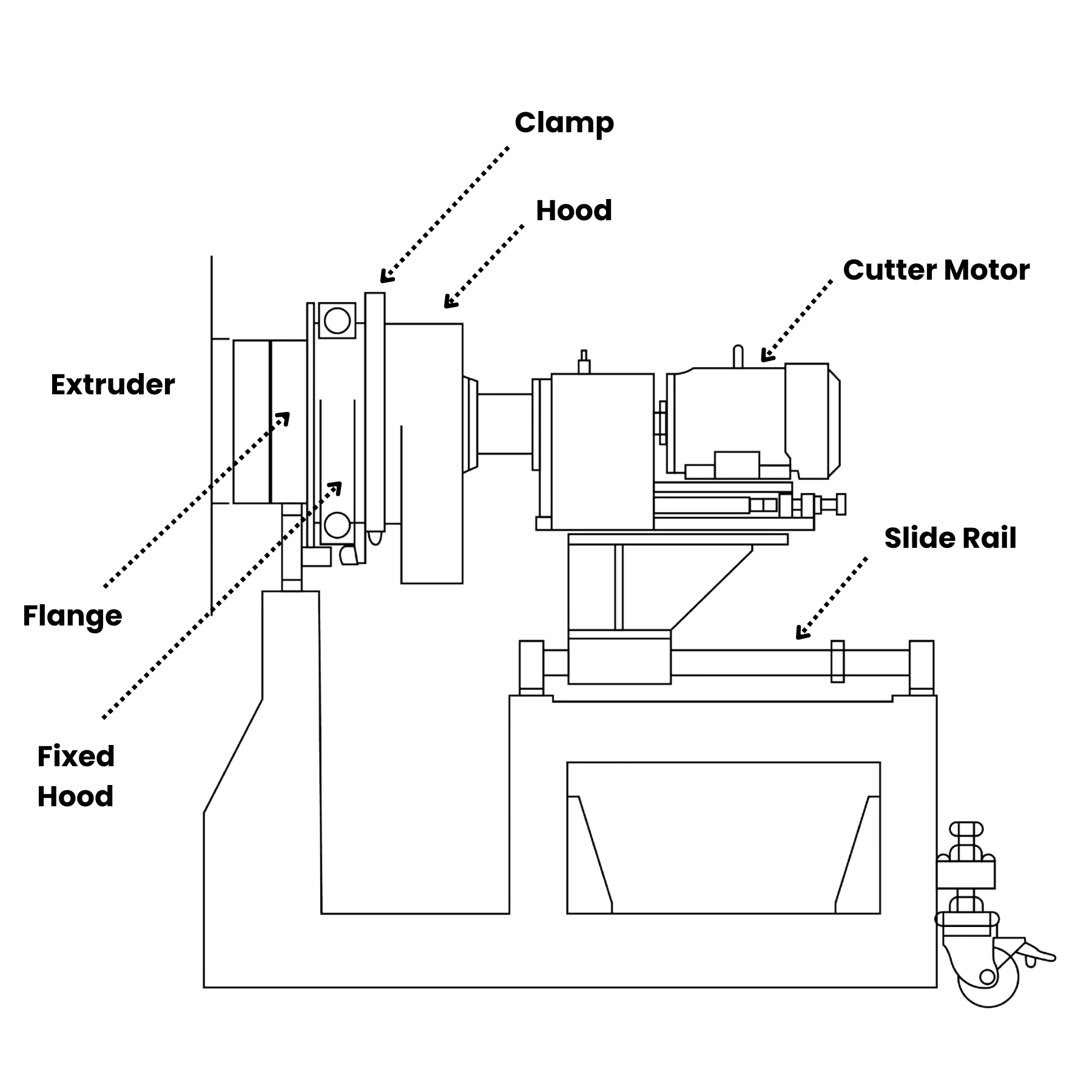

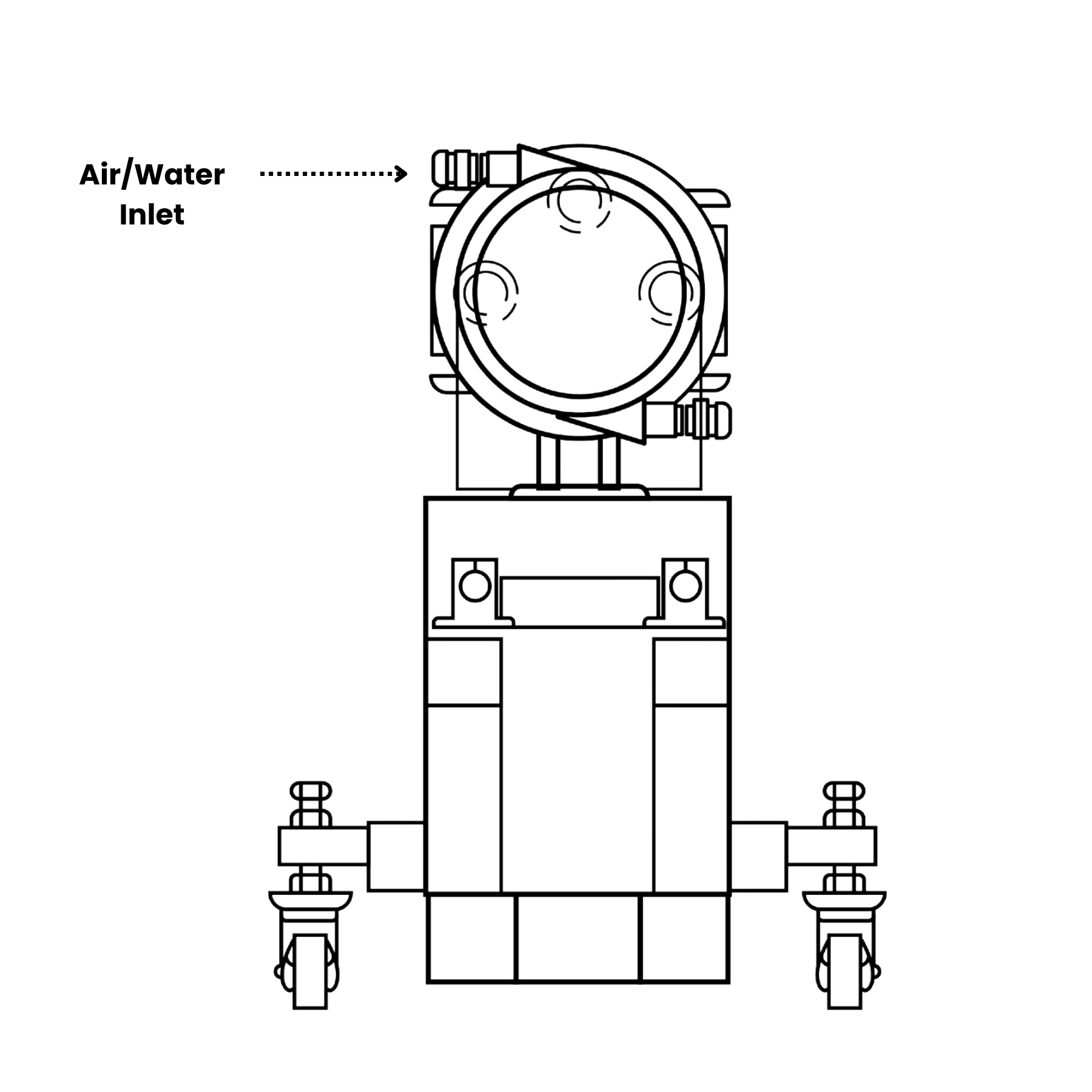

CTE’s Hot-Cut System is designed with a focus on easy maintenance and customizable pellet length, providing enhanced flexibility and operational efficiency. The system allows for quick removal of the hot cutter from the extruder using a carrier or slide rail, making maintenance and cleaning of the flange and cutter hood interior simple and convenient.

- Applications

- Product Catalog

Achieve Maximum Production Efficiency with Flexible Settings!

CTE’s Hot-Cut System offers flexible options for cutter configuration, allowing users to choose between 2 or 4 blades. By adjusting the motor’s rotation speed, the cutting speed can be precisely tailored to match the properties of the pellets. Additionally, the system provides easy switching between air cooling, water cooling, and mist cooling by changing the fluid supplied to the hood.

This high adaptability and flexible settings enable efficient pellet production, meeting diverse manufacturing needs with precision and ease.