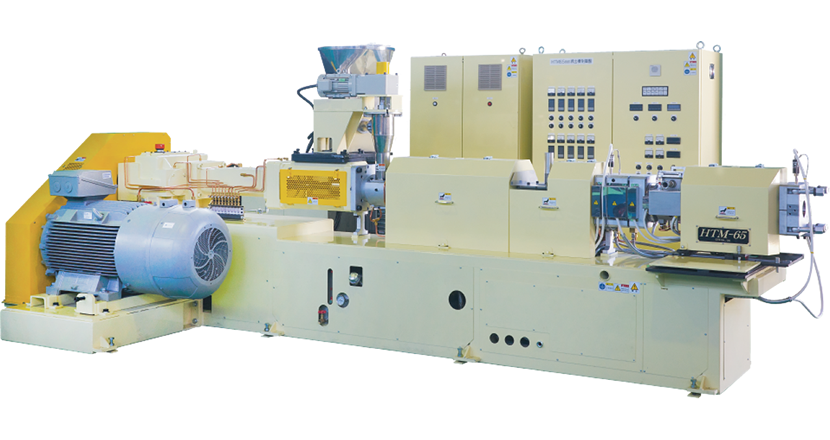

HTM Twin Screw Extruder

- #WoodFlour

- #WoodPlastic

- #WPC

- #ChemicalRecycling

- #MaterialRecycling

- #Recycling

- #PETFilm

- #NylonFiber

- #Regrind

- #Cellulose

- #InorganicFiller

- #Pulp

- #ContainerRecycling

- #Kenaf

- #Nanofiber

- #MagnesiumHydroxide

Counter-Rotating, Non-Intermeshing Twin-Screw Compounding Extruder:

Unmatched Performance for High-Filler Compounding!

The HTM Twin-Screw Extruder is a patented product built on CTE’s advanced technology, utilizing a counter-rotating, non-intermeshing twin-screw design. This system excels in high-filler compounding, providing superior kneading and dispersion capabilities.

The HTM effectively degasses air and gases trapped during material melting, ensuring optimal dispersion and preventing resin degradation. With its world-class performance, the HTM Twin-Screw Extruder is the leading solution for high-filled applications.

- Features

- Applications

- Formulation Guide

- Specifications

- Product Catalog

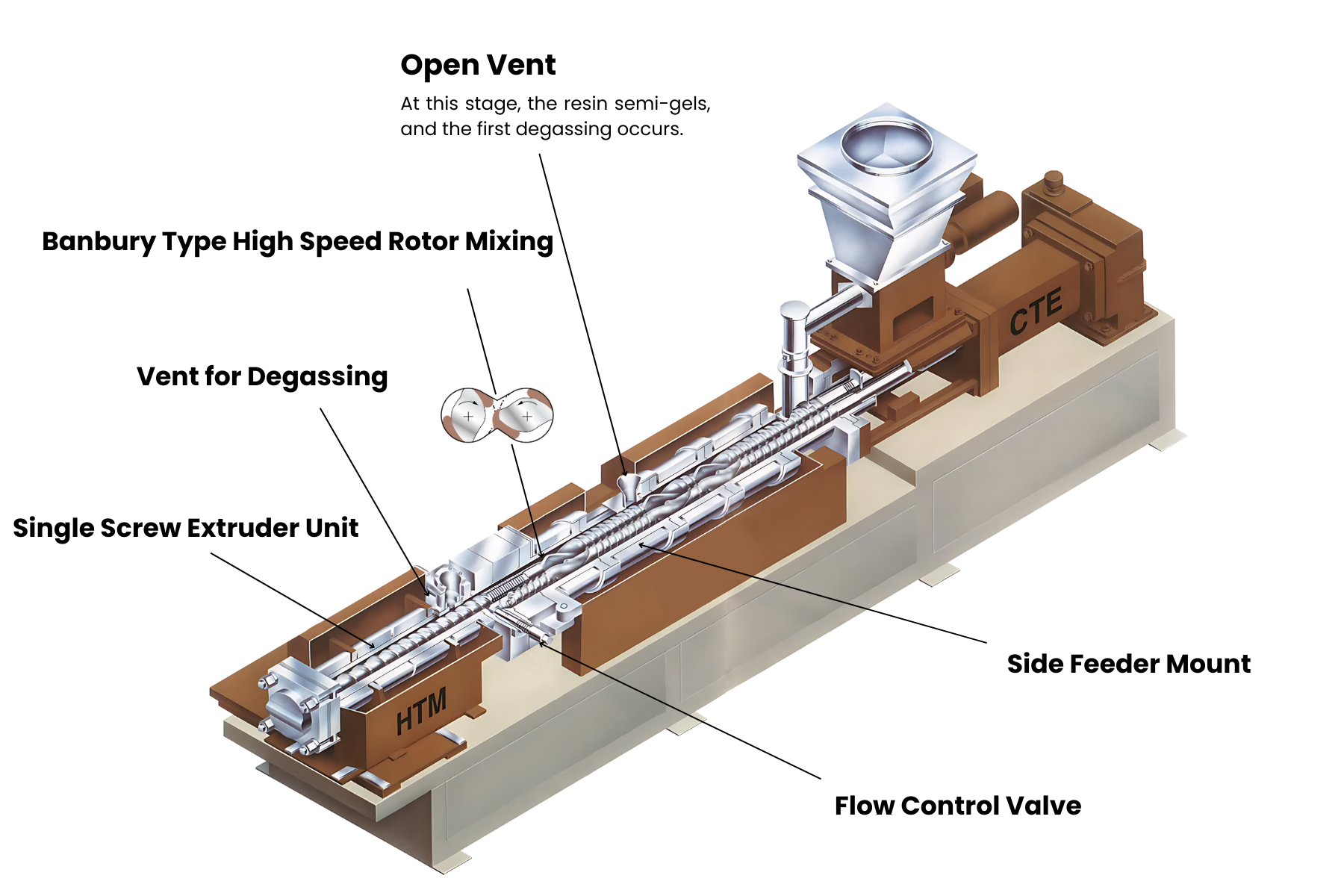

1. Superior Kneading Performance

The HTM Twin-Screw Extruder employs multiple high-speed rotors, similar to Banbury mixers, providing significantly higher kneading performance compared to co-rotating twin-screw extruders. After kneading and vacuum degassing, the material is extruded using a single-screw system, preventing over-kneading. This process enables low-temperature extrusion, with resin temperatures 10-20°C lower than conventional twin-screw systems, ensuring world-class operational control and superior performance.

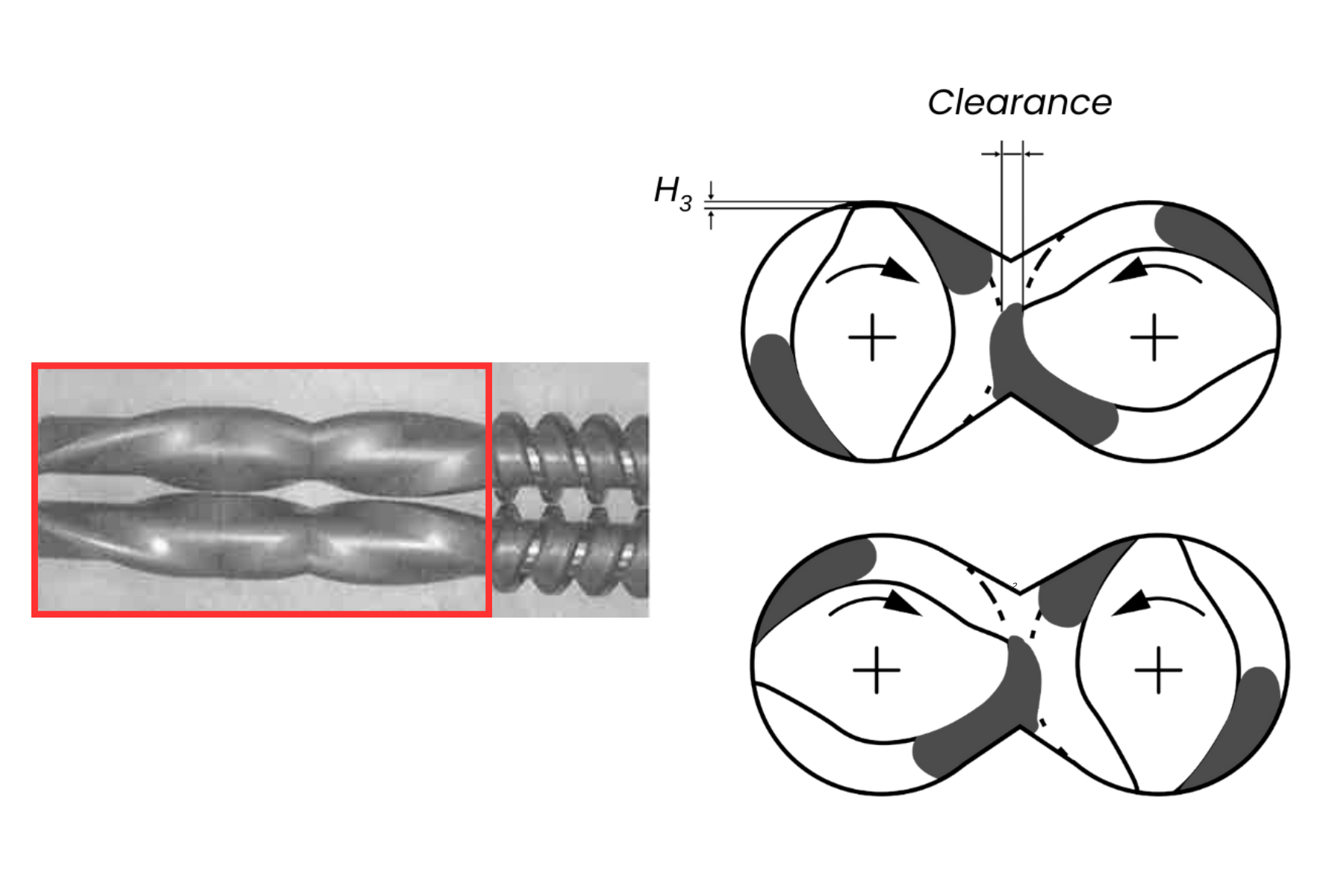

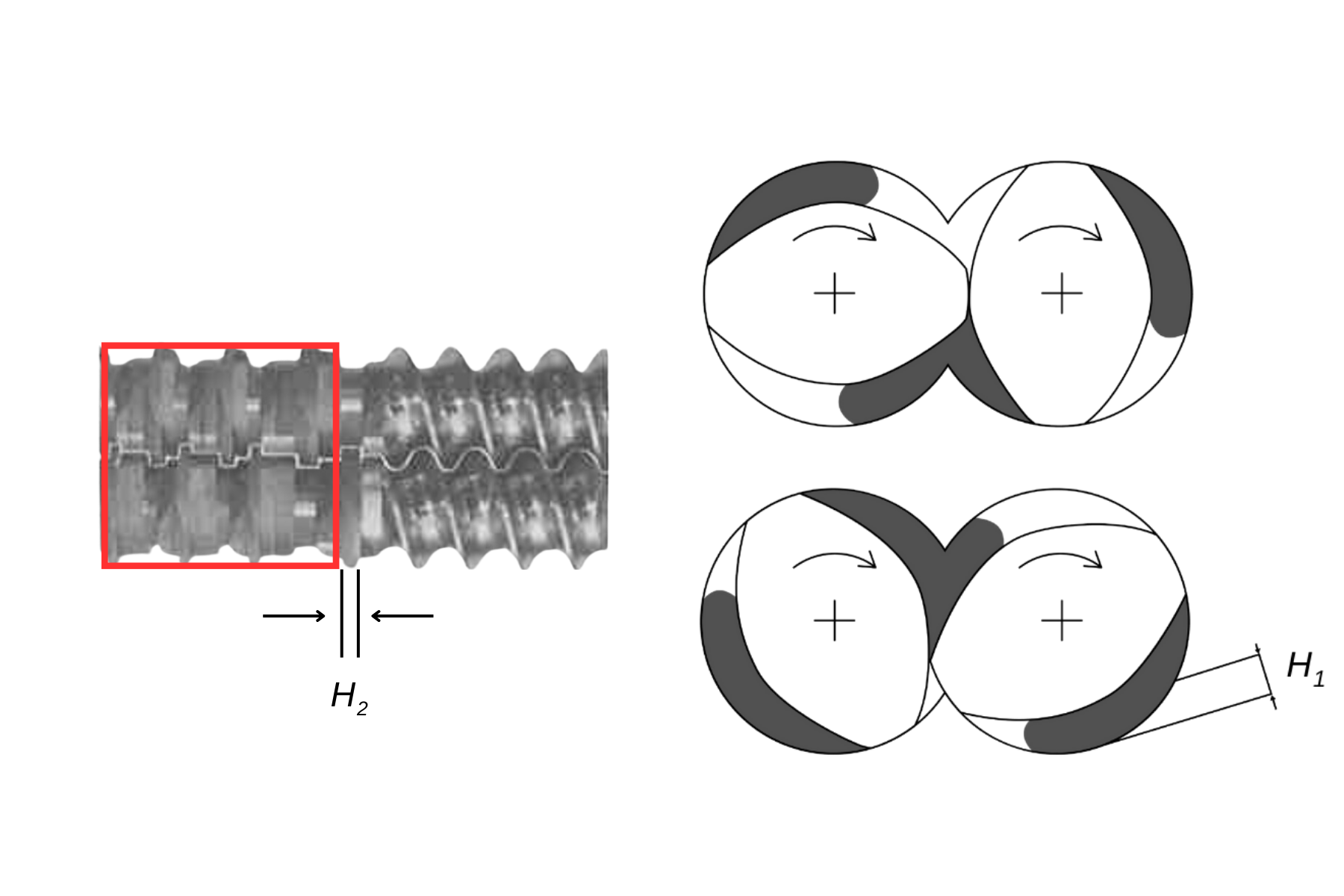

2. Kneading Comparison by Rotor Design

HTM Technology (Kneading Rotor)

Resin passes through the rotor’s clearance, undergoing high shear and even kneading. The repeated compression and release process controls heat generation, enabling efficient kneading and low-temperature extrusion.

Conventional Technology (Kneading Disc):

Resin remains in a high-compression state without release, receiving medium shear. This results in higher heat generation and less effective kneading compared to the rotor-based system.

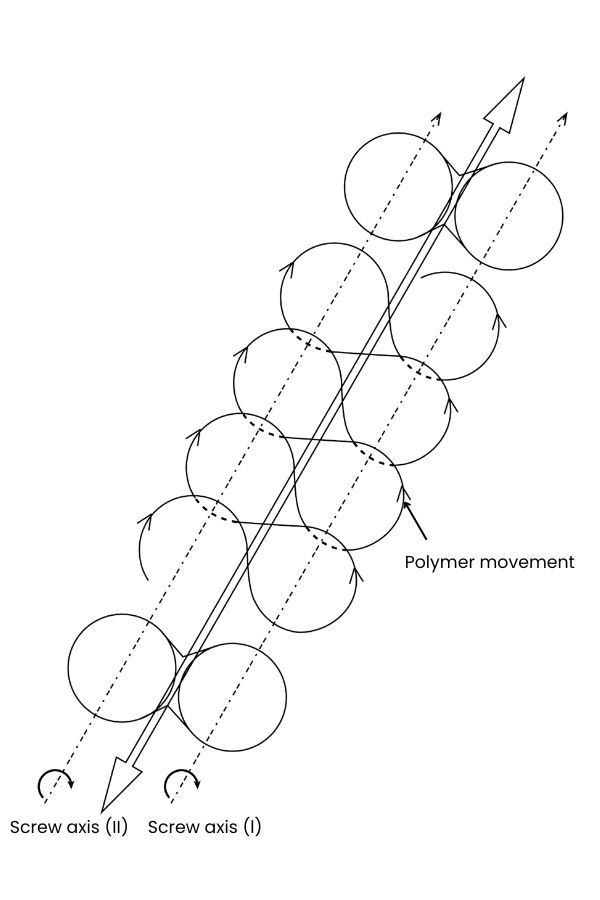

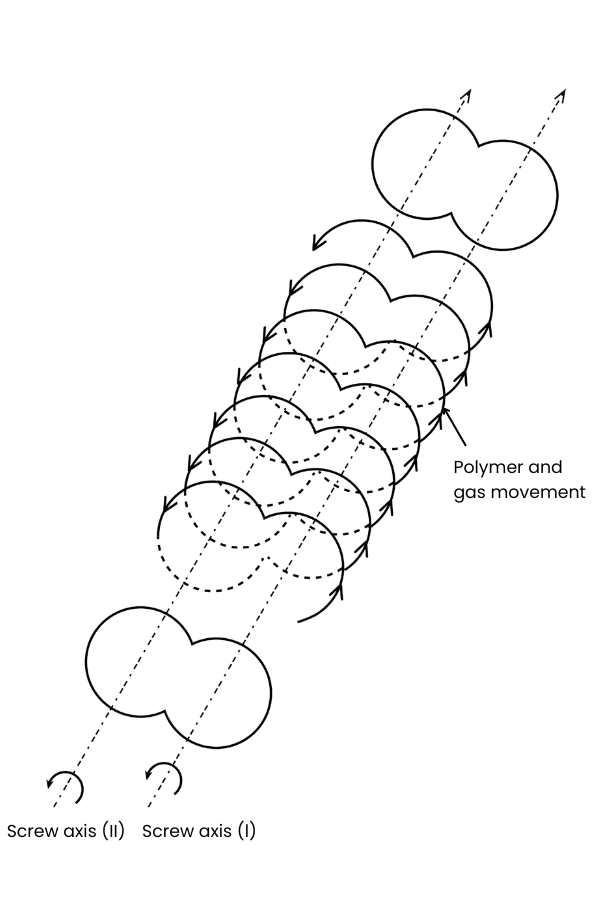

3. Resin and Gas Movement

HTM Twin-Screw Extruder

(Non-intermeshing, Counter-Rotating)

Conventional Twin-Screw Extruder

(Intermeshing, Co-Rotating)

4. Exceptional Degassing Performance

The non-intermeshing, counter-rotating design of the HTM system ensures outstanding degassing performance. This prevents air bubbles in pellets, eliminating molding defects. In conventional twin-screw extruders, intermeshing screws can cause poor degassing, leading to air expansion and feed neck issues. The HTM Tandem Compounding Extruder efficiently vents expanding air, preventing feed neck problems and ensuring superior pellet quality.

| Technologies | CTE’s Patented Technology (Counter-Rotating, Non-Intermeshing Type) | Conventional Technology (Co-Rotating, Intermeshing Type) |

|---|---|---|

| Gas Venting Design | The two screws do not intermesh, and a gap is maintained between them. Gas and air escape through the gap, resulting in excellent gas venting. | The two screws intermesh, and gas moves only along the grooves, resulting in poor gas venting. |

| Kneading | The resin is subjected to high shear by the rotors and is kneaded evenly. The repeated compression and release allow for high kneading with reduced heat generation, enabling low-temperature extrusion. | The resin is continuously sheared under high compression, leading to significant heat generation even with minimal kneading. |

| Low-Temperature Extrusion | After kneading in the twin-screw section, extrusion is performed at low temperature and low speed while cooling in the single-screw section. | The extrusion section after kneading is twin-screw, making it prone to heat generation. |

| Dispersibility | ◎ Excellent | 〇 Good |

| Shear Heat Suppression | ◎ Excellent | △ Needs Improvement |

| Gas Venting | ◎ Excellent | △ Needs Improvement |

| Material Feeding | ◎ Excellent | △ Needs Improvement |

| Productivity | ◎ Excellent | 〇 Good |

| Resin Temperature Control | ◎ Excellent | △ Very Inferior |

| Material Applicability | ◎ Excellent | △ Needs Improvement |

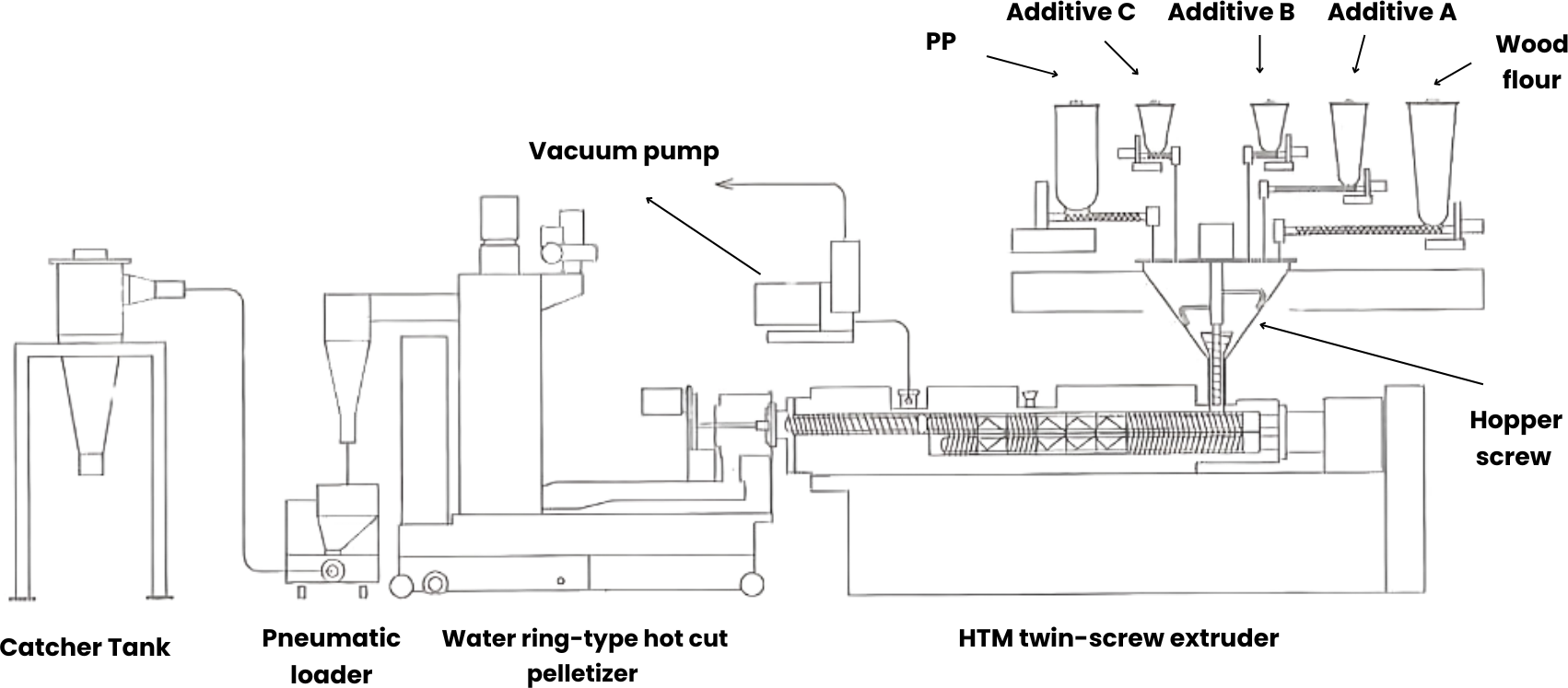

Superior Performance for Wood Flour Compounding!

The HTM Tandem Compounding Twin-Screw Extruder excels in wood flour compounding without the need for pre-drying. It allows direct feeding of non-dried wood flour (with a moisture content of 4-10%) and PP into the extruder for pelletization. This process enables significant reductions in equipment size, building footprint, and energy consumption, leading to substantial cost savings in production. Additionally, the system prevents wood flour from burning, maintaining the color quality of the final product.

Formulation Guide

Compounding and Extrusion Throughput Examples (kg/h)

The throughput values in the table are reference values.

Example: HTM-38 → Screw Diameter = 38mm

| Formulation Guide | Model and Extrusion Rate (kg/h) | Reference Values | ||||||

|---|---|---|---|---|---|---|---|

| HTM-38 | HTM-50 | HTM-65 | HTM-78 | HTM-90 | HTM-105 | HTM-120 | |

| Nylon Waste Yarn Ground Product (Bulk Density ≤ 0.05) | 50 | 100 | 200 | 300 | 400 | 600 | 800 |

| PET Film Ground Product (Bulk Density ≤ 0.04) | 50 | 100 | 200 | 300 | 400 | 600 | 800 |

| Rigid Regrind (MFR = 2~9, Bulk Density 0.6) | 100 | 200 | 400 | 600 | 800 | 1200 | 1600 |

| PP + Magnesium Hydroxide 60% | 100 | 200 | 400 | 600 | 800 | 1200 | 1600 |

| LDPE + Carbon 45% | 80 | 150 | 300 | 450 | 600 | 900 | 1200 |

| PP + Titanium Dioxide 60% | 80 | 150 | 300 | 450 | 600 | 900 | 1200 |

| PA6 + Glass Fiber 30% | 100 | 200 | 400 | 600 | 800 | 1200 | 1600 |

| Recycled PP + Wood Flour 50%~ | 50 | 100 | 200 | 300 | 400 | 600 | 800 |

| PLA + Wood Flour 10~60% | 50 | 100 | 200 | 300 | 400 | 600 | 800 |

| PBS + Cellulose 50~60% | 50 | 100 | 200 | 300 | 400 | 600 | 800 |

| PP + Talc 70% | 80 | 150 | 300 | 450 | 600 | 900 | 1200 |

Other various material compounding results are available. Please contact us for details.

| Specification | Model | ||||

|---|---|---|---|---|---|

| HTM-38 | HTM-50 | HTM-65 | HTM-78 | HTM-90 | |

| Screw Diameter / mm | 38 | 50 | 65 | 78 | 90 |

| Screw L/D | 42:01:00 | 42:01:00 | 42:01:00 | 42:01:00 | 42:01:00 |

| Screw Rotation (Max.) / rpm | 800 | 800 | 700 | 700 | 600 |

| Heater Capacity / kW | 40 | 60 | 105 | 140 | 180 |

| Motor Capacity / kW | 22~37 | 45~75 | 90~160 | 160~250 | 250~350 |

| Max Extrusion Rate (ABS) / kg/h | 200 | 400 | 900 | 1,400 | 2,000 |