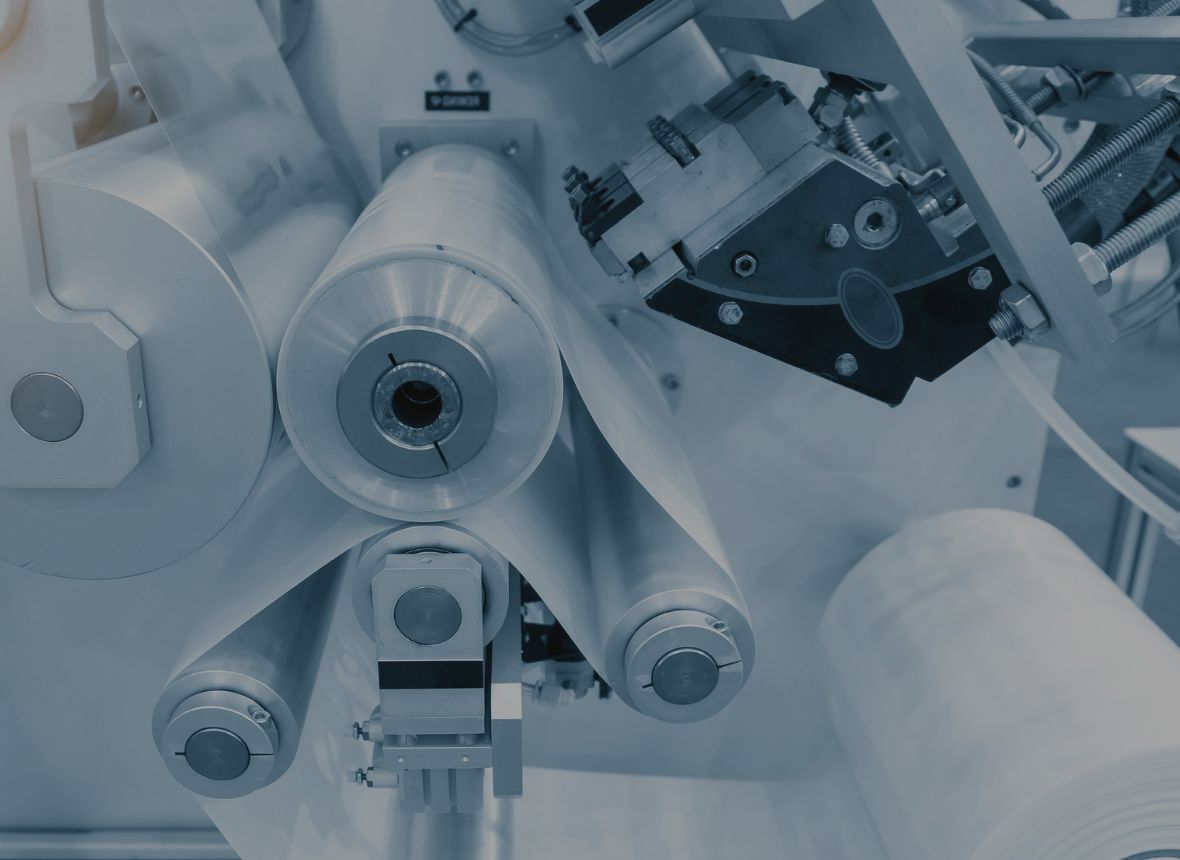

Optimization of Extrusion Process for Fine Talc High Filler Compounds

This article examines the extrusion process optimization of fine talc high filler compounds using CTE’s HTM Tandem Compounding Twin-Screw Extruder. Key findings include improved dispersion, stable throughput, and a more efficient alternative to conventional pre-mixing processes.

Evaluation of Dispersion and Throughput in Calcium Carbonate-Filled Compounds

Evaluation of dispersion and throughput in calcium carbonate-filled compounds using CTE's HTM Tandem Extruder, demonstrating superior performance over conventional twin-screw extruders.

Evaluation Test for High-Filler, High-Dispersion Compounding: HTM Tandem Twin-Screw Extruder

Discover the HTM Tandem Twin-Screw Extruder, designed for high-filler compounding with superior dispersion and enhanced output efficiency, ensuring optimal performance in plastic processing.

Advanced Biodegradable Resin Compounding with CTE’s HTM Twin-Screw Extruder

CTE’s HTM Twin-Screw Extruder minimizes resin degradation with advanced heat suppression and dispersion, enabling high-quality biodegradable resin compounding.

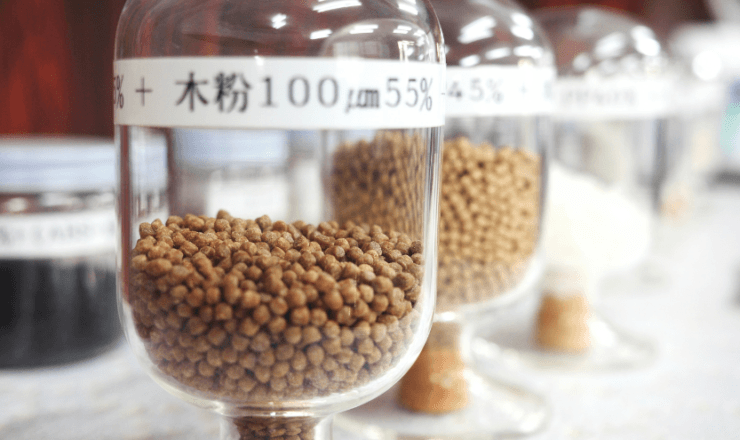

CTE’s Extrusion Technology: Biomass Raw Material Compounds

CTE’s HTM Twin-Screw Extruder transforms biomass compounding by tackling low density, moisture, and heat sensitivity, ensuring high-quality, sustainable materials for various industries.

Advanced Plastic Extrusion Solutions for Low Bulk Density Materials

Explore CTE’s advanced extrusion for low-bulk-density materials. The HTM Twin-Screw Extruder ensures optimized feeding, superior degassing, and efficient processing of biomass, fillers, and recycled plastics.

Interview: Masato Ito, CEO of CTE – Moving Toward a Sustainable Future with Plastics.

Masato Ito, CEO and President of CTE, sat down with us to talk about the company’s focus on extrusion technology, sustainability, and what the future holds. He shared insights on how CTE has earned its reputation through innovation and commitment.

Innovative Plastic Compounding with Carbon Capture and Utilization Technology

CTE is driving sustainability in the plastics industry by focusing on high-filled compounding, recycled plastics, and Carbon Capture and Utilization (CCU) technology. Central to this is the HTM Tandem Twin-Screw Extruder, designed to significantly reduce CO2 emissions and enhance eco-friendly plastic production.

Understanding Twin-Screw Plastic Extruders: High-Filled Compounding Explained

Plastic extruders are essential for producing various plastic products. This article breaks down the key mechanisms of plastic extruders, offering a simplified understanding of their role in manufacturing.

Plamirai: A Media Platform for Exploring the Future of Plastic

With growing environmental concerns, the term "plastic" is frequently discussed. In response, CTE and Zenken Corporation have launched "Plamirai," a platform focused on sustainable plastic solutions and the future of plastic.