Innovative Plastic Compounding with Carbon Capture and Utilization Technology

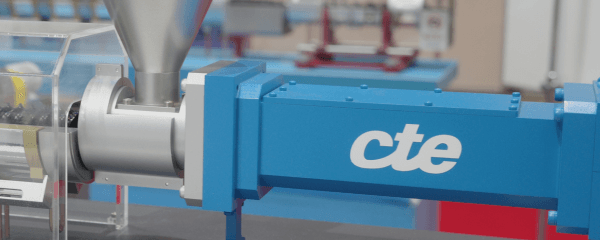

In the face of pressing global environmental challenges, reducing CO2 emissions has become a crucial objective. At CTE, we are committed to contributing to a sustainable society by advancing technologies in the plastics industry, particularly through innovative solutions in high-filled compounding, recycled plastics, and the use of CCU (Carbon Capture and Utilization) technology. Central to these efforts are our HTM Tandem Twin-Screw Extruders, which play a pivotal role in achieving these goals.

What is CCU Technology?

Carbon Capture and Utilization Technology captures CO2 emissions and repurposes them into valuable materials. Unlike Carbon Capture and Storage (CCS), which focuses on storing CO2, Carbon Capture and Utilization (CCU) converts it into new resources, such as plastic compounds and carbonates like calcium carbonate, making it a key technology in the quest for sustainability.

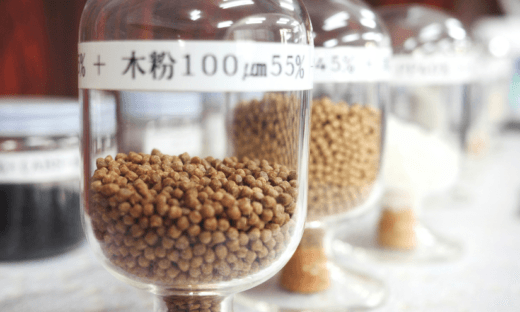

Challenges in Producing CCU Calcium Carbonate Compounds

Producing carbon capture and utilization calcium carbonate compounds poses several technical challenges. The large surface area, high impurity levels, and moisture content can adversely affect resins during compounding, leading to difficulties in high-filled compounding, resin degradation, and increased processing torque, complicating the production of high-quality plastic compounds.

HTM Tandem Twin-Screw Extruders: The Solution

CTE’s HTM Tandem Twin-Screw Extruders are specifically designed to manage high concentrations of carbon capture and utilization calcium carbonate, enabling high-quality compounding while minimizing resin degradation. The unique non-intermeshing, counter-rotating tandem screw configuration ensures that plastic compounds using carbon capture and utilization technology meet the stringent requirements of modern applications, making them suitable for a variety of industries.

Achievements and Future Prospects

The use of HTM Tandem Twin-Screw Extruders in producing plastic compounds with carbon capture and utilization technology marks a significant advancement in the field. As we continue to refine and expand these technologies, CTE remains at the forefront of innovation, driving advancements in high-filled compounding and recycled plastic processes. We invite partners to join us in pushing the boundaries of what’s possible with these groundbreaking solutions.

Towards Carbon Neutrality

Our HTM Tandem Twin-Screw Extruders play a crucial role in broadening the scope of carbon capture and utilization technology and contributing to carbon neutrality. As we refine these processes, CTE is proud to lead the way in creating a sustainable future through cutting-edge plastic extrusion technology—impacting industries and environments worldwide.