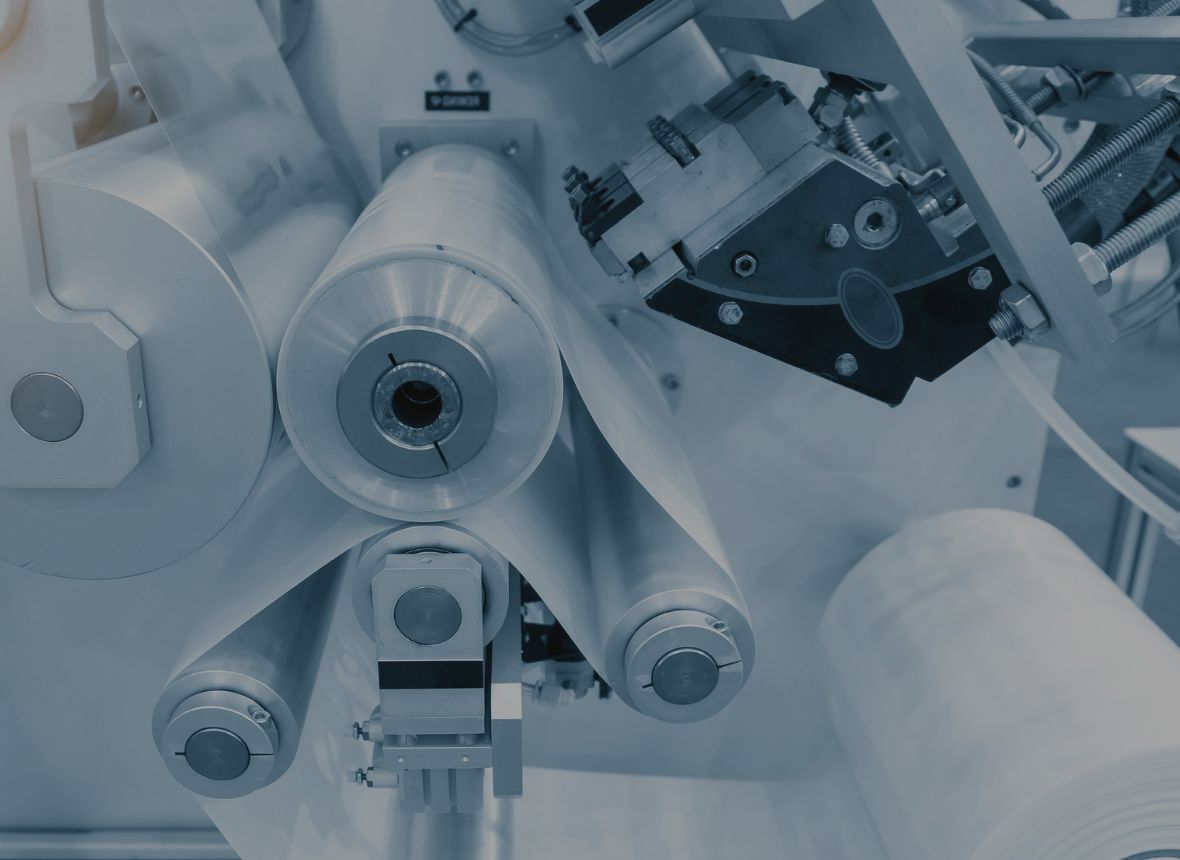

Sheet Extrusion Line by Steel Belt System

- #SheetExtruders

- #PPsheet

High-Performance and Efficient Sheet Manufacturing Solution

CTE’s steel belt sheet extrusion line delivers high-gloss, smooth-surface sheets using mirror-finish rolls and a mirror belt system. It is capable of producing thin sheets with easy thickness adjustment, and startup is quick, taking only 10-15 minutes. The system excels in producing transparent PP sheets with adjustable hardness. Its compact belt unit reduces manufacturing costs, as well as running costs like belt replacement, consumables, and power consumption.

- Applications

- Specifications

- Product Catalog

Versatile Sheet Production for Food Trays to Optical Materials

Our steel belt sheet extrusion line offers superior mirror-finish surface quality, enabling rapid cooling for high-transparency PP sheet production. These transparent PP sheets are ideal for applications such as food trays, clear files, and cases. Additionally, the smooth surface and high optical properties make this system suitable for producing high-performance PC and cyclic polyolefin sheets.

| Specification | Details |

|---|---|

| Extruder Model | IPE-65, IPE-90 |

| T-Die Width | 850mm, 1250mm |

| Belt Width | 800mm, 1200mm |

| Winding Speed | 0-20m / min |

| Sheet Width | 650mm, 1050mm |

| Sheet Thickness | 0.1mm – |

| Throughput | 200kg / hr |

| Power Capacity | 300kW (IPE-90) |